In today’s fast-paced and increasingly digital world, shippers are facing new challenges and opportunities. The ability to accurately predict demand is more critical than ever, directly impacting operational efficiency, cost-effectiveness and customer satisfaction. Demand planning, a key process in supply chain management, involves forecasting the demand for products to ensure they can be delivered in a timely manner to meet customer expectations. The goal is to strike a balance between having sufficient inventory levels to meet customer needs without having a surplus, which can tie up resources and increase costs.

Traditionally, demand planning has relied on historical sales data and manual processes. But these traditional methods often fall short. Factors such as labor force changes, economic shifts, severe weather, natural disasters or global crisis events can significantly impact demand, making it difficult to make accurate predictions based on past trends alone.

Shippers have often found themselves reacting to changes in demand rather than anticipating them. This reactive approach can lead to inefficiencies, missed opportunities and increased costs. A sudden surge in demand can result in stockouts, lost sales and dissatisfied customers. On the other hand, overestimating demand can lead to excess inventory, increased storage costs and potential waste. Without the ability to accurately predict demand, shippers are left navigating the market without a clear view of future demand.

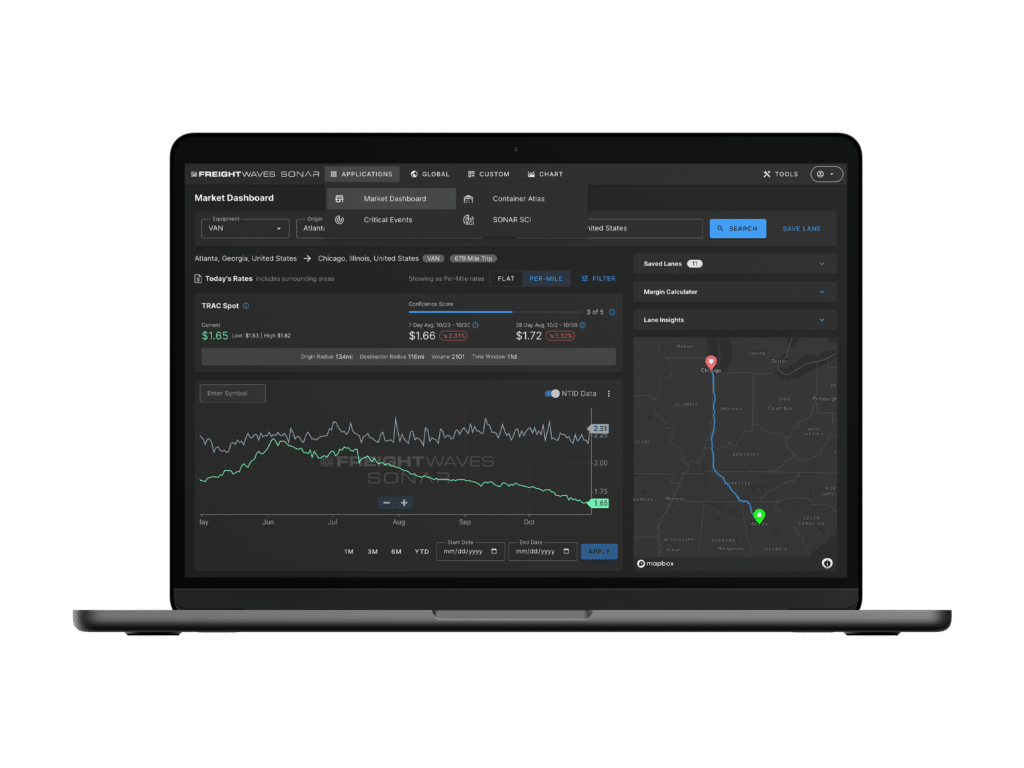

In recent years, the power of supply chain data has become increasingly apparent. This data, encompassing a wide range of near real-time sources, provides valuable insights that can significantly enhance demand planning. By leveraging it, shippers can make more accurate forecasts, improve operational efficiency and better meet customer needs.

In this white paper, we will explore how supply chain data can revolutionize demand planning for enterprise shippers. We will delve into the limitations of traditional demand planning methods and then highlight the transformative potential of supply chain data. We will examine how this data can be used to improve demand planning, discuss the benefits and challenges and provide recommendations for shippers looking to leverage supply chain data for demand planning. Our aim is to provide you with valuable insights that can help you navigate the complexities of demand planning and make informed decisions that drive success.