In logistics, many vital processes remain outdated and subject to manual management. Some of the largest enterprises are still using old and obsolete methods and platforms. This leaves shippers, carriers and freight managers alike vulnerable to disruption. Embracing a new and improved interoperability-driven approach that applies advanced logistics technology helps freight management parties realize improved profit margins.

Embracing this new approach through a unified logistics technology stack will help streamline many daily processes and cut back on wasted resources. And conservation across time, working hours, resources, and energy throughout the supply chain network becomes a reality. But first, it’s essential to understand why and how interoperability is vital to maximized tech ROI.

Automation combined with interoperability makes management platforms more functional and practical for day-to-day use and implementation. It provides a unified interface for the implementation of innovative processes and systems. This, in turn, can help reverse the biggest problems associated with outdated methods. Such problems include:

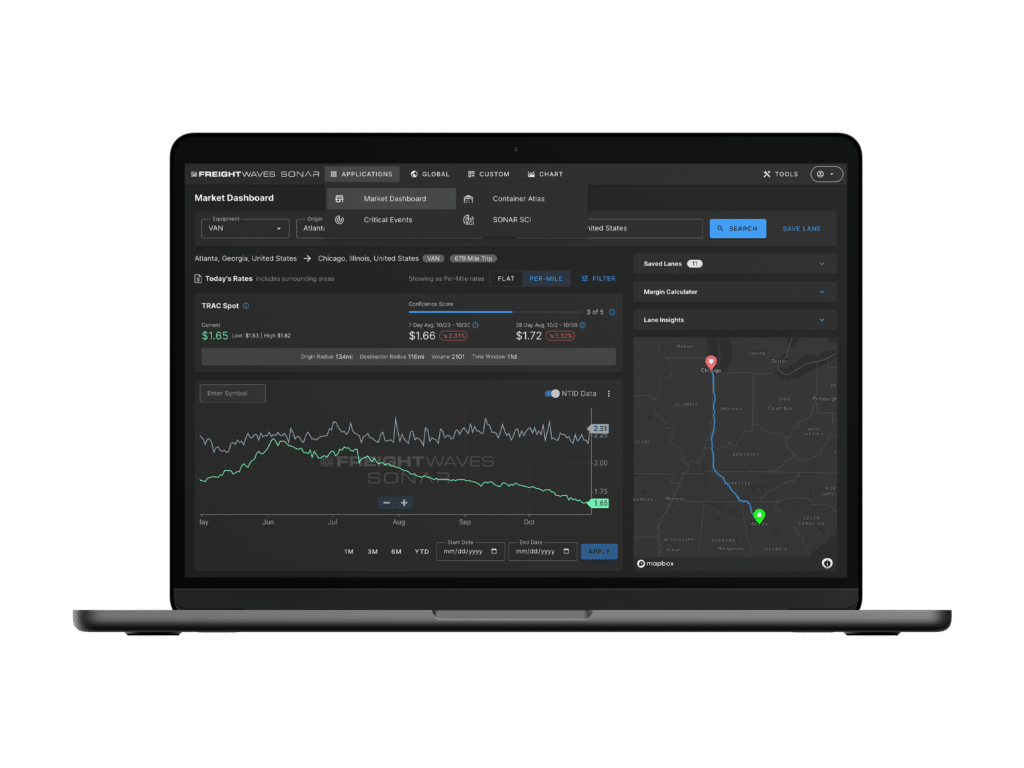

Over time, the smallest variations and redundant processes mean higher costs for supply chain planning and execution. And since no organization can improve what they cannot measure, it all tracks back to limited benchmarking potential and a continuance of poor, biased and manual process management. However, with modern, interoperable logistics technology, managers can easily automate tasks traditionally performed manually or those that need separate interfaces and tools. The contemporary approach allows for multiple jobs and processes to occur within a single, accessible platform. For instance, choosing between contract versus spot rates grows much simpler when shippers access the full picture.

Interoperability within individual systems eliminates the burden of managing multiple systems. And there are additional opportunities to let automation do the “hard work.” This is where robotics process automation (RPA) comes into the picture and makes logistics technology use faster and more practical within the supply chain.

RPA falls into place alongside other digital tools that promote automation and digitization of standard processes. According to The Enterprisers Project, “RPA is a form of business process automation that allows anyone to define a set of instructions for a robot or ‘bot’ to perform. RPA bots can mimic most human-computer interactions to carry out a ton of error-free tasks at high volume and speed. If that kind of automation technology sounds sort of, well, boring, that’s by design. RPA is ultimately about automating some of the most mundane and repetitive computer-based tasks and processes in the workplace.” A well-designed, automated system will have features that work by improving speed, efficiency, accuracy and affordability.

In the supply chain, that amounts to capturing and applying data from across freight forecasting platforms to maximize management through the system of record.

The unified interfaces of logistics technology interoperability boost load management and execution. However, it can go much further than many realize. Interoperability can improve remote monitoring processes to make the administrator’s job simpler and more streamlined. Supply chain managers can track freight KPIs to ensure carrier compliance, manage work schedules, and continuously improve operations. Also, interoperability further ensures shippers and carriers stay focused on their top priorities, such as trucking costs. That is the true beauty and appeal of modern swivel-chair functionality processes and platforms within the shipping and logistics industry today.

Embracing a modern, interoperable approach to logistics technology has already been shown to benefit all freight management parties across the industry. Managers and 3PL partners see improved profit margins and a more streamlined process with automation and innovation at the helm. And since a well-designed automated system will improve speed, efficiency, accuracy and affordability throughout the entire supply chain, making additional improvements or upgrades grows easier to justify. It’s time to leverage an interoperable freight forecasting engine to maximize enterprise shipper efficiency. Get started on the path to efficiency; request a FreightWaves SONAR demo by clicking the button below today.