One year ago, we wrote a white paper in which we estimated that the top five paper and packaging companies in the U.S. spent a whopping $7 billion to $9 billion on domestic freight transportation in 2019. Despite the revenue declines posted by the industry in 2020, we believe that industry freight spend is just as high as pre-pandemic levels due to growth in packaging demand and higher freight rates.

Like many industries, 2020 was challenging for the paper and packaging industry. The largest company in the industry posted an 8% revenue decline in 2020 on lower demand for printing papers due to pandemic-related disruptions.

Meanwhile, demand for packaging improved during the pandemic and is expected to grow further going forward, which is causing the industry’s largest player to focus on its corrugated packaging business while spinning off its paper business.

In contrast to the softer packaging prices experienced in 2020, companies have experienced considerable inflation rates in 2021, which has made packaging an area of greater focus for shippers. Packaging inflation is clearly part of a larger inflationary trend that has created headaches for shippers also facing higher costs for raw materials, labor, contract manufacturing and freight.

There are no signs of the pressure on costs abating. On its second-quarter analyst call, Unilever stated that its packaging costs rose 7% in just one quarter from 1Q21 to 2Q21, with an expectation that overall costs will continue to accelerate. For all that we talk about freight rates, that 7% sequential increase in packaging costs exceeded the 4% increase in freight rates over the same time period.

While the broad inflationary backdrop provides an appropriate time for paper and packaging companies to raise prices, we believe that raising prices is not the entire answer and it is clear that most large shippers are turning over every rock to find efficiencies throughout their supply chains.

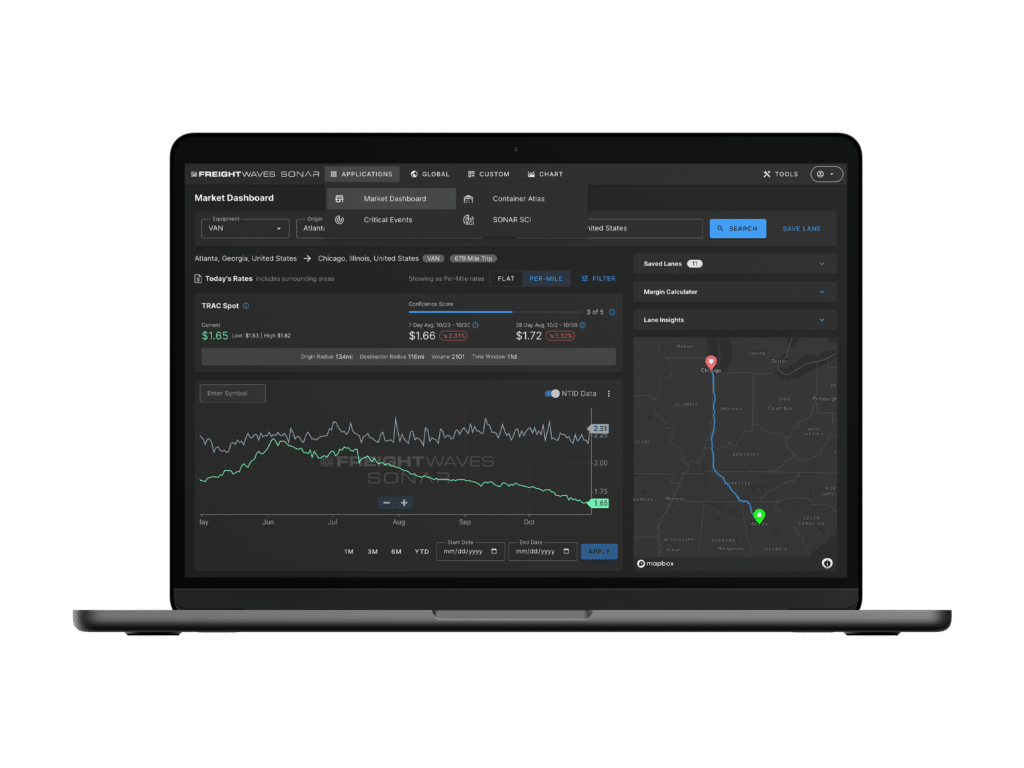

With those thoughts in mind, we recommend that paper and packaging shippers leverage all data available when negotiating contracts and managing day-to-day freight movements. We estimate that the largest paper company could save ~$23 million in freight spend pretax from a hypothetical reduction in freight spending of 1%.