From a financial standpoint, transportation cost analysis remains focused on determining the value of the resources used to execute a given shipment and goes well beyond benchmarking. The total value of resources, man-hours, construction, equipment, maintenance, fees, and other costs must be accurately estimated for expense prediction to be effective. Without clear budgeting and cost-prediction measures, the transportation network will be unable to accurately plan for increases and decreases in expenses. Moreover, this kind of analysis does not focus on who ends up paying which expenses in the end. Rather, it focuses on establishing standards for all costs that come with all loads and how those costs move over time. Let’s take a closer look at how such an analysis provides more actionable insights that help shippers find and leverage meaningful capacity.

The challenges of limited transportation cost analysis

Without a clear picture of what money is coming in and going out of the supply chain, common challenges and disruptions can have an even greater impact. Some of the most common issues that arise from a lack of accurate transportation cost analysis and data tracking include the following:

- Inability to track data and respond to it in real-time.

- Lack of visibility and insight into common observable costs.

- Lack of planning to plan for rises in fees and expenses.

- Poor net revenue per truck (NETREV) in the fleet.

- Limited data sharing within the chain.

- Inability to secure profitable loads and orders.

- Difficulty in executing the most profitable moves.

- Failure to hold carriers and brokers accountable for shortfalls or errors in billing practices.

- Ongoing wasted resources.

Together, these challenges demonstrate why transportation cost analysis is critical to keeping the supply chain operational and functioning at a profitable and scalable level. But it’s also important to think about how a comprehensive analysis amplifies basic benchmarking capabilities.

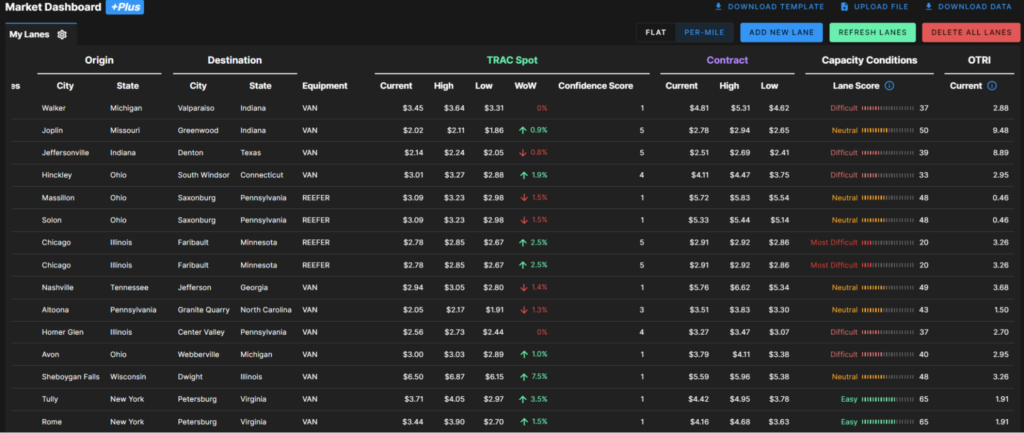

True transportation cost analysis goes well beyond benchmarking to analyze, monitor and forecast trends that can be used to the shipper’s advantage

A trend that continues among shippers nationwide is better monitoring and utilization of analysis within the supply chain. Knowing when fees tend to rise, and charges commonly fluctuate can help shippers know when and how to secure the best freight rates. The key focus of transportation cost analysis remains an important component of supply chain and logistics planning. Combining common freight KPIs with cost analysis and tracking can give management a clearer picture of what path to take for short-term and long-term success. And if shippers know more about how carriers price freight, they are better able to identify those trends based on market signals and pre-empt carrier pricing changes.

Consider this fact. According to the Small Business Chronicle, “Finding a reliable and affordable carrier isn’t a one-time scenario. You could be missing out on competitively priced options if you’re not constantly building relationships with carriers and getting quotes for different services. Failing to diversify your carrier relationships also puts your company at high risk of being stuck in a lurch if your sole carrier suddenly goes out of business. You’ll definitely lose money if you cannot keep your customers happy by delivering their products, so poor carrier diversity puts you in a lose-lose position.” As a result of better freight data application, it’s easier and more effective to find such carriers while tendering loads at proper rates that are less likely to incur rejection and move more efficiently.

Core needs to enable proactive analyses of transportation costs

For any supply chain management team to make the most of transportation cost analysis, there remain several key components that must be present. All the data and analysis will mean little if these points remain absent from the network:

- Acquisition of and access to all internally and externally available data by all involved team members.

- Access to national and localized market benchmarking reports for up-to-date information.

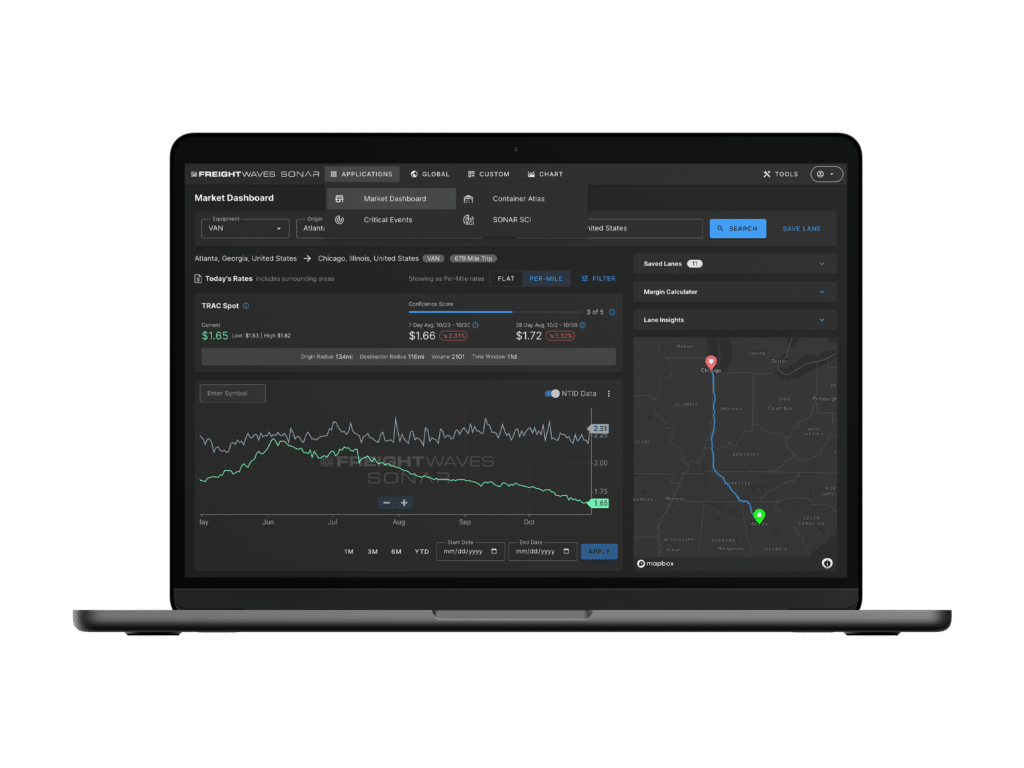

- Monitoring of freight trends noted from data analysis platforms and dashboards, as well as market expert predictions and trends.

- Advanced freight analytics to understand headhaul versus backhaul strengths and weaknesses across all U.S. origin and destination pairings.

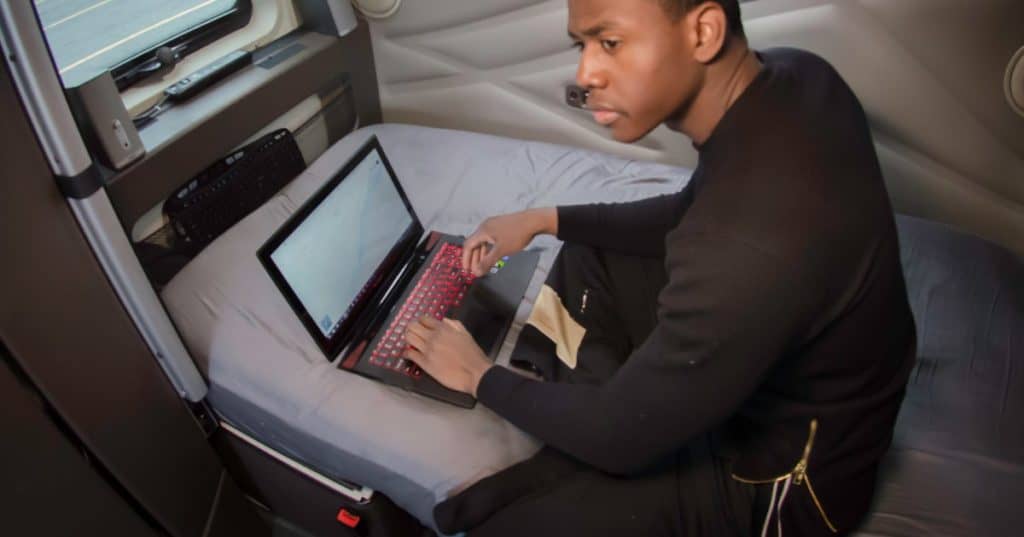

- Centralized lines of communication to quickly share real-time freight data and information, including the use of a cloud-based freight data platform to access advanced insights from anywhere with internet connectivity.

- Access to digital and automated dashboards for capacity acquisition and knowing when to scale mini-bid activity to avoid major financial setbacks.

By letting the data do the talking, logistics managers and supply chain directors can realize the true value of strong and accurate transportation cost analysis. It’s that simple.

Generate stronger, more proactive carrier pricing strategies based on near-real-time data insights

Transportation cost analysis sheds light on budgeting and spending within the supply chain. This in turn makes it easier to identify emerging trends and issues to keep freight spend under control.

Staying on top of trends within the industry is critical for survival now and in the future. And like any cost analysis, it begins with seeing the data inside and outside of your organization, using a platform like FreightWaves SONAR. Get started by requesting a FreightWaves SONAR demo today.