Supply chain visibility has become a vital element in today’s ever-changing market. As reported by Project 44, “Gartner projects that 50% of global companies will have implemented or invested in “real-time transportation visibility solutions.” Companies are rapidly adopting and using real-time data to clearly understand challenges to better mitigate unexpected problems when they arise. With more agility and transparency, based on accurate data-driven choices, implementing essential visibility tools empowers shippers with practical foresight into predicting rate changes in real-time.

This helps to realize fewer tender rejections, increases an understanding for requests for proposal (RFPs) bringing optimal deals, and improves lead time planning to secure capacity procurement. In fact, logisticians should consider these top five use cases of increased visibility and data within logistics and how they improve throughput.

Unexpected problems are bound to arise. A carrier can be delayed, or a pickup can be missed or lost. Mitigating these occurrences has always involved clear communication between both parties—traditionally done through phoning the client, emailing, or faxing after the headache has been realized. This could possibly mean hours lost, and money spent. Although these methods are foundational, they don’t provide the agility of real-time updates that supply chain visibility tools can accomplish. Imagine knowing when a delayed truck is arriving and knowing where a missed or lost load is in one transparent digital platform. This incredible benefit saves time, money, and alleviates the headache for both carriers and shippers alike.

Being able to leverage real-time data to predict rate changes like a delay in deliveries due to bad weather is extremely helpful. Taking a proactive approach and utilizing the many benefits that supply chain visibility tools offer prevents much of the unnecessary disruptions. Managing these exceptions with proficient tools allows for better insight and will assist in creating a more effective on-the-go strategy for unexpected problems.

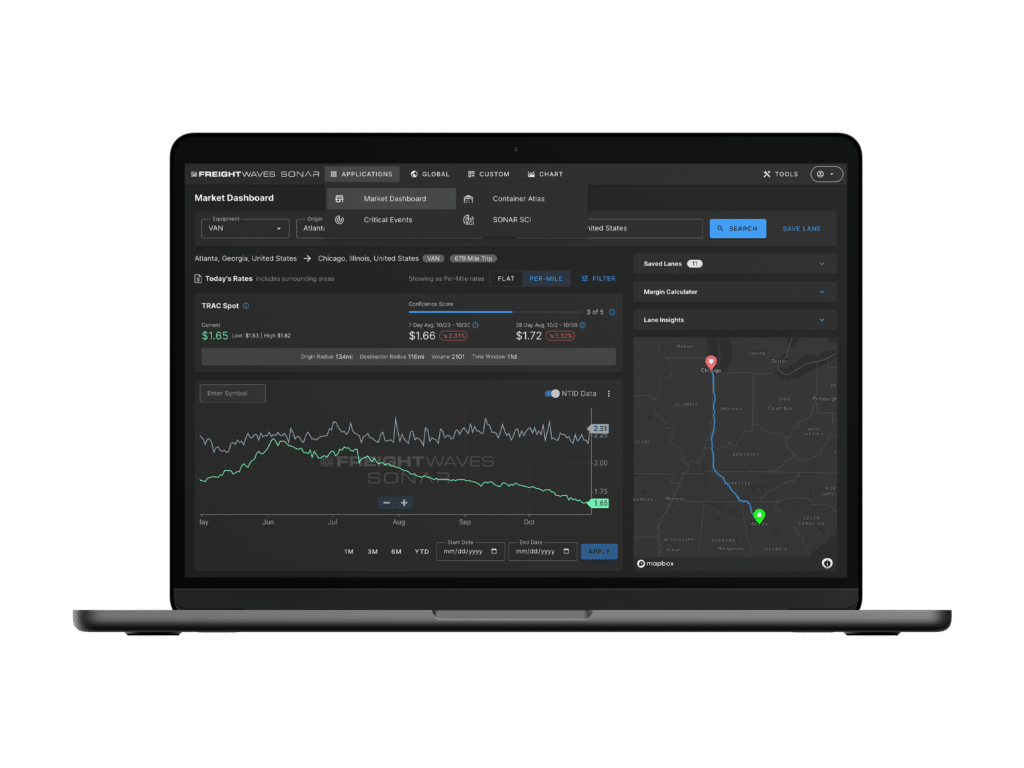

Another proactive way to improve freight execution goes back to better, faster-tendering processes. For instance, shippers could leverage the outbound tender rejection index (OTRI) to gauge how easy it is to cover a load and as such, define the best rate that will attract a given carrier.

For example, the above image shows an OTRI of 27.15 as of the close of business on March 2, 2021. While a slight difference from the more recent peak toward February’s ending, it is still significantly higher than any other value seen in February 2021 as a whole.

Therefore, the risk of rejection declines, and shippers are able to better move more freight at a lower cost. After all, even a delay of a few days amounts to higher carrying costs. So faster acceptance by carriers through proactive tendering means lower costs overall too. And again, it hangs on the ability to capture and apply data to make informed decisions, going back to the need for increased supply chain visibility.

Handing annual or short-term RFP processes is yet another opportunity to apply visibility to understand supply chain needs. Increased understanding of changing RFP dynamics, including carrier standards for pricing, differences within individual markets, overall capacity constraints, and generalized market instability can go a long way in helping shippers keep freight spend under control. After all, an annual or short-term RFP is about making sure shippers are able to secure the best freight rates and best capacity available, while the opposite applies to carriers. Depending on the freight management segment, the goal is to either lower or maximize costs incurred per shipment. And shippers that have access to more data can make a more informed decision, determine when it may be necessary to onboard new carriers or lanes, incurring additional RFP processes for all applicable needs.

Increase supply chain visibility is about knowing what is happening, why it is happening, what it means for the future, what shippers need to do to preempt those changes and being able to do it all in real-time. That is why more shippers and carriers have grown accustomed to the idea of supply chain visibility as tantamount to end-to-end supply chain visibility. Increased visibility also improves replenishment processes deriving from increased lead time planning and the ability to secure capacity with less hassle. It is a complex process that is continuously allowing shippers to lower their carrying costs, increased throughput, meet customer expectations, and keep freight spend under control.

Effective supply chain management carries the distinction of increased visibility, maximum transparency, lower costs and faster execution. It all begins by getting access to real-time data. And if up-to-the-minute data is unavailable, the next best thing is near-real-time data, such as tender data from the prior day’s close. That is where an advanced freight forecasting platform like FreightWaves sonar can add the most value, providing the measure of insight needed into all freight markets and helping shippers stay strategic. Request a FreightWaves SONAR demo by clicking the button below