While freight mode optimization remains a top priority for companies, there’s an option that’s often overlooked – cross-carrier or intermodal shipping. This mode is often used interchangeably with multimodal, but it’s entirely different. As explained by TradeLens, this cross-carrier form of “transportation is defined as freight movement via more than one mode of transportation. Goods are packed inside containers, trailers, or other storage methods, for clean transfers between logistics service providers (LSPs) that do not have to handle goods during shipment directly.” Thus, freight management parties need to know a few things about when to choose this cross-carrier form of transportation over another freight mode.

Since intermodal involves a clean transfer between carriers or LSPs, it is reasonable to assume another factor went into choosing this mode over another. In many cases, using intermodal stems from an inability to obtain the lowest freight costs and best service multimodal options from a single carrier. As a result, documentation, collaboration and seamless planning go into intermodal freight management.

As a rule, all rail modes involve a form of intermodal freight transportation. However, not all moves may include rail. That difference can be incredibly confusing for small and mid-size shippers. However, the best way to approach it is to recognize that any shipment involving rail should include an analysis of all cross-company freight carriers and LSP capabilities. The strategy of rating all carriers that work with external LSPs and other carriers will ensure all documentation is appropriately shared and routed accordingly.

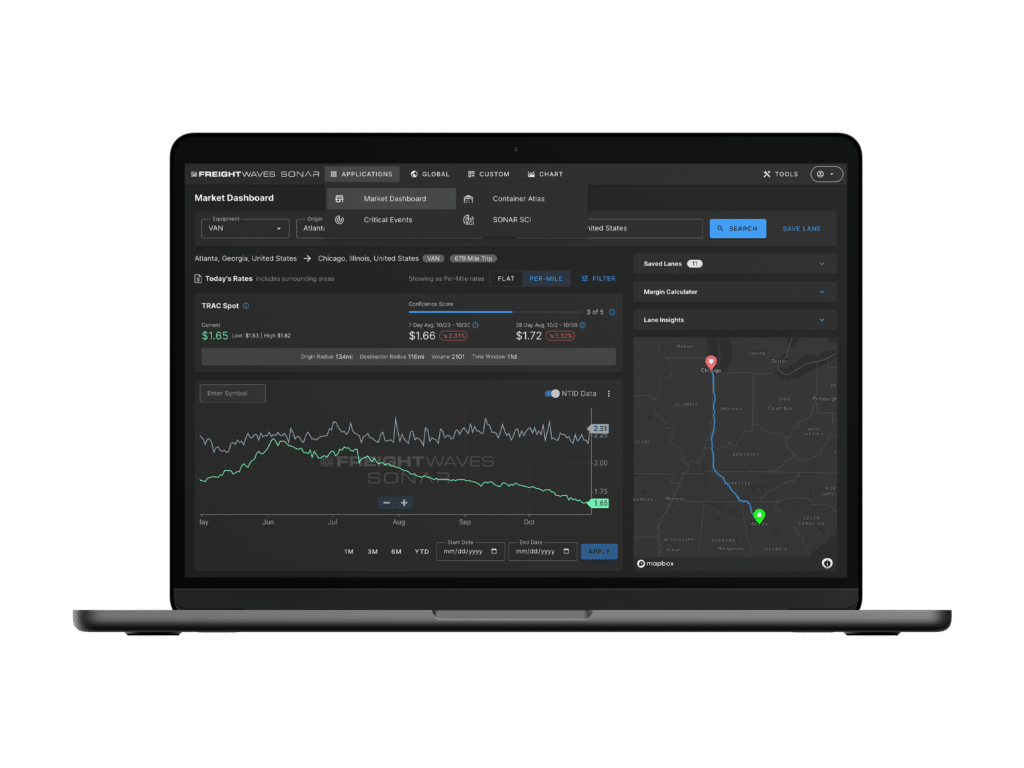

Using data and insights

as your guide to freight

bidding negotiations

While working with a single carrier possesses significant advantages, applying a form of transparent transportation across multiple carriers can be particularly beneficial for time-sensitive shipments. These form the precursor to many international logistics capabilities. And cross-carrier transportation is another step in which companies may avoid excess dwell time, demurrage or drayage costs. As Merrill Douglas of Inbound Logistics explained, “applying a comprehensive strategy to using intermodal versus other modes can go a long way in reducing total risk and maximizing savings. After all, relying on a single carrier to manage all steps increases the risk of overspend and results in delays. Ultimately, more carriers involved in the process and moving freight will greatly increase efficient, timely freight transportation.”

Choosing intermodal is not ideal for many shipments. This is particularly true among high-value shipments and finished products. Since the shipment involves movements between carriers, it is subject to additional touchpoints. As a result, the risk of damage or loss can be too significant to warrant leveraging this form of transportation. As a result, loads tendered for this unique transportation method lend themselves to procurement and manufacturing raw materials and unfinished products. However, that is not the final rule. This mode of transportation can be especially valuable when lead times begin to increase.

Since intermodal represents another way in which transportation may evolve, all freight management parties must realize that this form of transportation is not necessarily included with existing contracted freight rates. In other words, carriers and LSPs that offer this form of transportation may need to enter a new freight bidding process with shippers and vice versa. Unfortunately, that means recognizing that a new freight bidding negotiation process could lead to potential setbacks and higher costs during other time periods.

For example, undergoing a freight bidding process during peak season, concerning an annual contract, is counterproductive. However, using a mini-bidding process may be a viable option. Regardless, it is crucial to take stock of all modes and market conditions, ranging from dedicated services through cross-carrier moves, before requesting a new freight bid to justify the renewed bidding strategy. Conducting a new bidding process must use the latest, most accurate freight rates for planning freight moves, which have a natural implication and benefit for other transportation actions. Of course, if all existing tenders are experiencing a higher-than-expected rejection rate, it may be time to consider intermodal transportation.

In the world of freight management, one thing is clear. A potent combination of multimodal, intermodal, dedicated modes and fleets, mini-bidding strategies, annual contracts, and a watchful eye on the true freight market rates are essential to making the most informed decisions and keeping freight spend under control, as well as reducing the chances of tender rejections. To learn more, request a SONAR demo now.