Freight procurement can feel like an exercise in futility: You spend months analyzing your transportation spend and carrier performance, putting lanes out to bid and deciding how to award freight, only to end up in the spot market at the last minute or rebidding all of your lanes again if the market shifts.

Far too much effort is wasted arriving at rates and awarded volumes that neither party — shipper nor carrier — is actually committed to. Misaligned incentives on both sides keep parties from establishing strategic relationships. The current request for proposal (RFP) process makes most shippers’ goal — to get great service at a reasonable price — unnecessarily difficult to achieve. In this blog post, we’ll go through the five reasons why freight procurement is broken.

1. Shippers’ carrier networks experience big turnover.

The average shipper experiences 50% turnover or more in its carrier network annually. That fact alone demonstrates the current RFP process puts shippers in relationships with carriers they end up not wanting to do business with, and it makes it harder for them to maintain relationships with the carriers that service their freight well. An RFP process should help logistics professionals and transportation managers find and keep the best providers, not endlessly churn through transactional relationships.

2. Processes remain opaque.

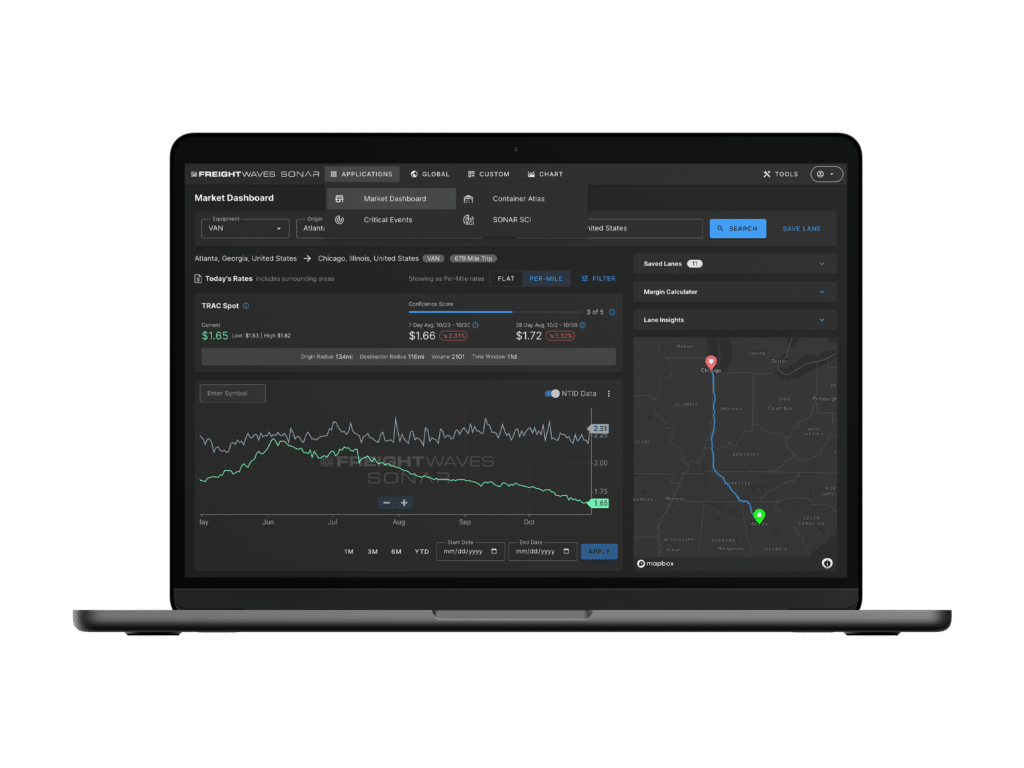

RFP processes are opaque on both sides of the market, resulting in a highly inefficient guessing game. Transportation providers responding to a bid have no idea where their rates stand relative to competitors on any given lane, plus they lack insight into the shipper’s rationale for conducting the bid in the first place. For a transportation provider, successfully navigating the RFP process usually implies a high-touch relationship, multiple rounds of bidding, negotiation, and tradeoffs — not at all like the lightning-fast, automated pricing exercise they would prefer. Shippers also are putting a finger to the wind when they send their lanes out to bid, trying to gauge overall carrier sentiment at the same time they’re awarding freight. A lack of a shared reality and industry-standard benchmarks that would keep all parties on the same page makes the RFP process unclear and inefficient.

3. Bid cycles are time-consuming and costly.

Large RFPs are time-consuming and expensive to conduct, which is why the very largest shippers use their leverage to secure multiyear contracts. Even the vast majority of Fortune 500 shippers can’t do that, so instead they compile carrier scorecarding, analyze their spend, run analyses, put lanes out to bid, begin evaluating their responses and typically conduct more than one round of bidding. All of this work, though, doesn’t represent an investment in a permanent relationship, process or piece of organizational infrastructure. Instead, these contracted commitments come and go. The cost associated with RFP cycles doesn’t help the organization long term. It just gets their freight — hopefully — covered for the next few months, so anything that can be done to reduce this cost should be done.

4. Service and price are often at odds.

One of the core problems with the traditional RFP process is that price and service are often at odds. If the product the shipper is looking for can be boiled down to “great service at a reasonable price,” there’s no way to efficiently purchase it on the market. Instead, transportation managers typically rank carriers in their routing guides in ascending order of price, so that cheaper carriers are awarded more freight. But those carriers will abandon that low-paying freight the day they discover a more lucrative way to move their trucks. Shippers try to mitigate this risk by creating service thresholds for the providers invited to the most important RFPs, but the same contradiction remains. The cheap carrier the shipper is most incentivized to use becomes the one least interested in servicing the freight if there are better options.

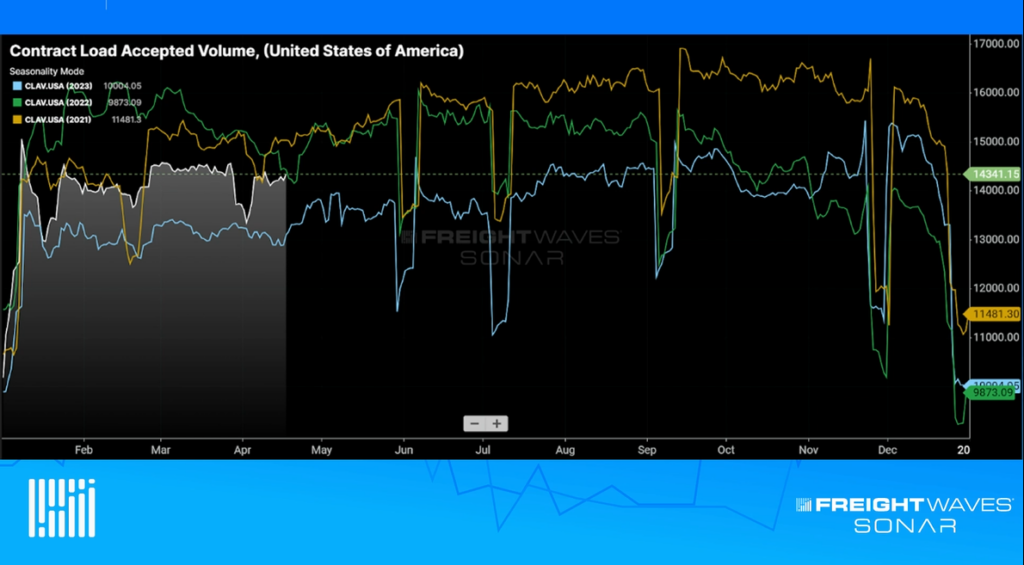

5. Volatility can make contract rates obsolete quickly.

Finally, the classic problem with annual RFP cycles is freight market volatility. In a volatile year, contract rates have moved up or down by up to 20%, and spot rates have moved up or down by more than 40%. Agreeing on a single rate that will be honored for 12 months under those conditions seems absurd, and indeed the “contracts” of the trucking industry are often no more than polite fictions and wishful thinking. What happens when your routing guide falls apart because the market moved more than 10% away from your contracted rates? Your team scrambles to run an unplanned mini-bid, trying to isolate the underperforming parts of your network and get your carriers back on board. Or you bite the bullet, pull out the checkbook and build large, multiload projects for the spot market and hope you don’t blow through your transportation budget.

Freight procurement is broken and outdated, a vestige of a functioning system that shippers and transportation providers use despite how it performs. What shippers want — great service at a reasonable price — is almost impossible to secure using the traditional RFP process.